Servo Repair Company

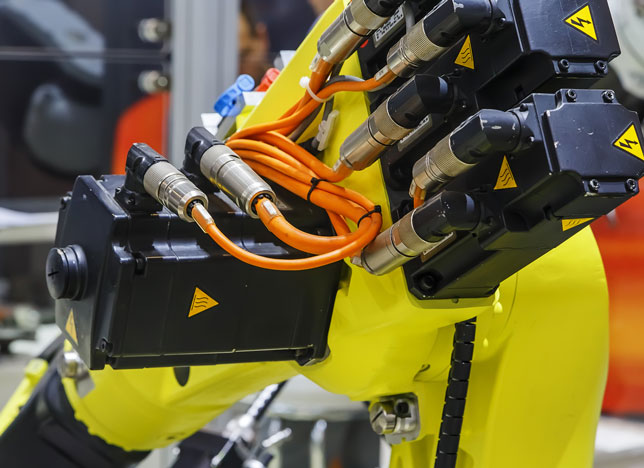

Established in 1993: Accu Electric Motors Inc. is the leading independent repair facility of specialized servo motors, drives and robotic equipment in North America.

With over 15+ engineers and 45+ employees, Accu is committed to providing quality products and services that continually meet and exceed our customer’s expectations.

- More than 200,000 units repaired.

- All major servo brands serviced, as well as unique proprietary brands.

- Over 1000 different servo makes and models

- Over 85 years cumulative experience

- Around the clock shifts allow us to have 24 hour rush turnaround / Rush technical support service.

Why Accu Electric Inc.

We are an ISO:9001 Quality Assurance, and CSA explosion proof repair certified facility with over 40,000 sq ft of space between our robots and main shop. Our technicians are well qualified and they possess over 120+ accumulative years of hand-on practical experience in repairs.

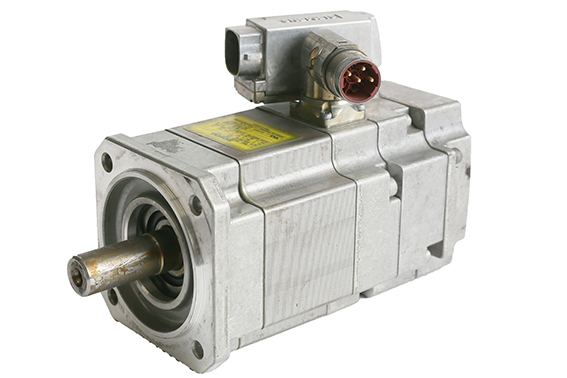

With full capabilities on testing the electro-mechanical properties of motors as well as handling the full repairs requirements in house such as rewinding of motor’s winding and stator winding, replacement of bearing, spindle bearings, roller bearings and even linear bearings, commutator and armature repair and rebuild, feedback alignment, broken magnets and design change requests.

Repair of feedback devices like encoder, resolver, hall-effect sensor and setup their properties wave form, offset angle timing and voltage and keep the testing records, that include reverse generated voltage i.e. back EMF, feedback signal and alignment data. We are fixing damaged shaft, housing and sleeve end bells of motors, winding, stators, and as far as broken magnets. We have a large number of spare parts in our inventory to decrease your downtime to a minimum.

Procedure for sending in a Servo Motor Repair

- As we receive your shipment, we assign an RMA tracking number

- After doing a thorough inspection we give the estimate on cause of failure, what’s required to get it back up and running, and quote you the repair

- After repair and reassembly the lead technician will adjust the alignment angle and run-test the motor on the original OEM drive, not a standalone universal drive as our competitors. This ensures the motor works exactly how it would in your system. Our vast investment in harnesses and drives makes this process quick, safe, and cost-effective for you to get your machine back online fast.

- Once completed the motor is packed, with foam in a secured box for shipping, and customer is sent the tracking number.

200,000

Units Repaired

85

Years Of Experience

24

Hour Technical Support

Repair vs. Replace

Should You Repair a Failed Servo or Replace one?

- Why did the motor fail? What were the symptoms?

- Is there a spare unit on hand that can be put into service?

- Is the machine down? What is the cost of continued downtime?

- What is the cost of a new motor? Is it immediately available or is there a lengthy lead-time until it can be delivered and put into service?

- What is the warranty (in-service) for a repair?

- Can you find a servo repair vendor willing to provide a free quote? Can they do so in a timely manner?

- Is the repair vendor reputable? How long have they been repairing servo motors?

- Even if the repair is more than 50% the cost of buying a new motor, can the machinery be running more quickly than buying new?